As a professional factory specializing in broom heads and poles, we’ve served clients from over 20 countries in the past decade. During this process, we’ve noticed that threaded head styles for broom-pole connections vary significantly by region—a detail closely tied to local usage habits, market standards, and even product safety regulations. Today, we’ll break down these differences and share how our factory tailors solutions to meet global demands.

1. Common Threaded Head Styles by Region: Why They Differ

Every region’s threaded head design has its “logic”—it’s not just about “twisting to connect,” but about adapting to local needs. Here are the 4 most representative styles we’ve encountered:

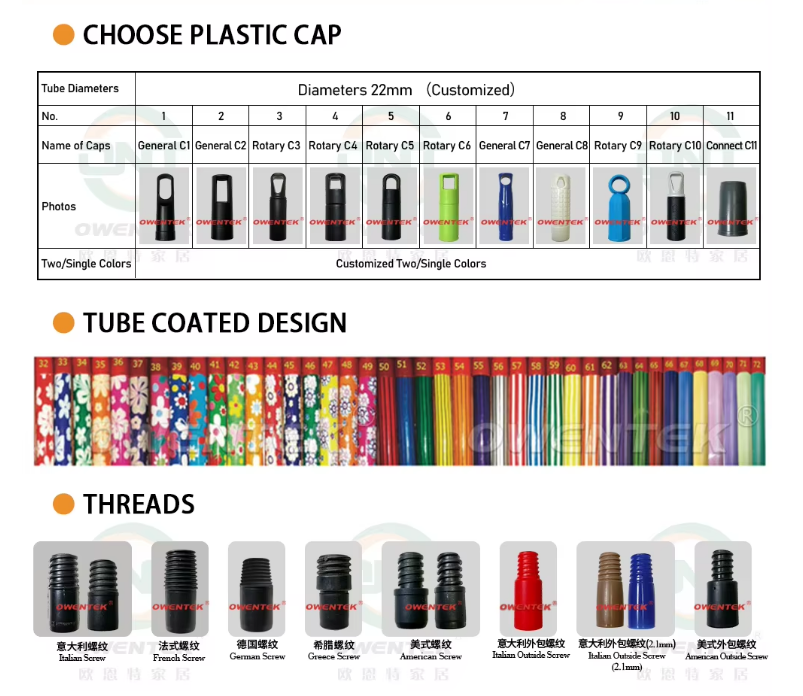

● European Market: M10/M12 Metric Fine Thread

European countries (such as Germany, France, and Italy) mostly adopt M10 or M12 metric fine threads for broom pole connections. The threads are dense (1.25mm-1.5mm pitch), and the connection is tight—this design addresses two core needs:

First, European households and commercial spaces (like cafes, boutiques) often use brooms with heavier, thicker poles (usually 25mm-30mm diameter) for long-term durability; fine threads ensure the pole and head won’t loosen during frequent use.

Second, EU safety standards require “zero risk of detachment” for daily cleaning tools—our factory’s European-style threaded heads undergo 5,000+ twist tests to ensure no slipping, fully complying with EN 17284 (EU standard for cleaning tools).

● North American Market: 3/8-16 UNC Coarse Thread

The U.S. and Canada prefer 3/8-16 UNC coarse threads (imperial system). With a larger pitch (1.5875mm) and thicker thread diameter, this style focuses on “quick assembly”—a key demand for North American retailers and consumers:

Most North American broom poles are lightweight (aluminum or hollow plastic), and users often assemble/disassemble poles for storage (e.g., fitting into small closet spaces). Coarse threads let users twist the pole and head together in 2-3 turns, saving time.

Our factory’s North American-style threaded heads also add a “rubber anti-loose ring” at the thread base—solving the common problem of coarse threads loosening due to vibration during sweeping.

● Southeast Asian Market: M8 Metric Short Thread

Countries like Indonesia, Thailand, and Vietnam mainly use M8 metric short threads (thread length 15mm-20mm). This design is a response to local climate and usage scenarios:

Southeast Asia has high humidity year-round, so broom poles are often made of low-cost, moisture-resistant plastic (instead of metal). Short threads reduce the contact area between the pole and head, preventing mold growth in thread gaps. Additionally, local consumers prefer “compact brooms” (for small homes or street stalls)—short threads keep the connection stable while avoiding overly bulky joints.

● Middle Eastern Market: M10 Knurled Thread

In Saudi Arabia, the UAE, and other Middle Eastern countries, M10 knurled threads are popular. The thread surface has a raised “knurled pattern” (like small ribs), which serves two purposes:

First, Middle Eastern households often use brooms for outdoor cleaning (e.g., patios, courtyards), where sand and dust easily enter thread gaps—knurled patterns create small “channels” to let debris fall out, avoiding stuck threads.

Second, the knurled design improves grip during assembly—even with oily or dusty hands (common in outdoor cleaning), users can twist the pole tightly without slipping.

2. Our Factory’s Advantage: One-Stop Customization for Global Threaded Styles

Understanding regional differences is just the first step—our core strength lies in customizing threaded heads and poles to match any market’s needs, with 3 key guarantees:

● Full Compliance with Local Standards

We have a dedicated R&D team that tracks thread standards for 50+ countries. For example:

● Flexible Production: From 100pcs Samples to 100,000pcs Bulk Orders

Whether you need a small batch of M8 short threads for a Thai retailer or 100,000pcs of 3/8-16 UNC threads for a U.S. chain store, our 8 production lines can adjust:

● Cost Optimization: No Middlemen, Factory-Direct Pricing

As the source factory, we cut out intermediate suppliers—for example, the cost of M10 knurled threaded heads for Middle Eastern clients is 15% lower than that of trading companies, while ensuring the same quality.

3. Let’s Collaborate: Your Local Market Expert for Broom Threads

If you’re struggling with “thread mismatch” when exporting brooms, or want to launch a new product line that fits a specific country’s needs, we’re here to help.

Send us your requirements (e.g., target country, thread style, pole material), and our team will provide:

Contact us today via the “Inquiry” button below—let’s turn regional thread differences into your market advantage!